TECHNICAL DATAS

| SIP outer sealing | SIP outer sealing |

| Motion | Motion |

| linear | linear |

| Direction of pressure | Direction of pressure |

| unidirectional | unidirectional |

| Operating pressure (MPa) | Operating pressure (MPa) |

| 0,5 | 3 |

| Linear speed (m/s) | Linear speed (m/s) |

| 3 | 3 |

| Diameter range (mm) | Diameter range (mm) |

| 12 to 70 | 15 to 200 |

| Housing | Housing |

| split |

split |

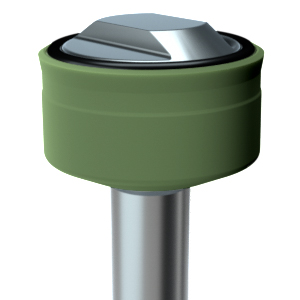

| Type DK | SIP outer sealing |

|---|---|

| Motion | linear |

| Direction of pressure | unidirectional |

| Operating pressure (MPa) | 0,5 |

| Linear speed (m/s) | 3 |

| Diameter range (mm) | 12 to 70 |

| Housing | split |

| Type DL | SIP outer sealing |

| Motion | linear |

| Direction of pressure | unidirectional |

| Operating pressure (MPa) | 3 |

| Linear speed (m/s) | 3 |

| Diameter range (mm) | 15 to 200 |

| Housing | split |