The sealing action of these static seals is achieved by elastic deformation of their cross-section in a housing designed to DIN 11864. This type of seal is suitable for all automatic and manual cleaning processes.

In food processing, jointing of pipes and flanges always represents a weak point in relation to hygiene. Therefore aseptic pipe joints are standardized in DIN 11864.

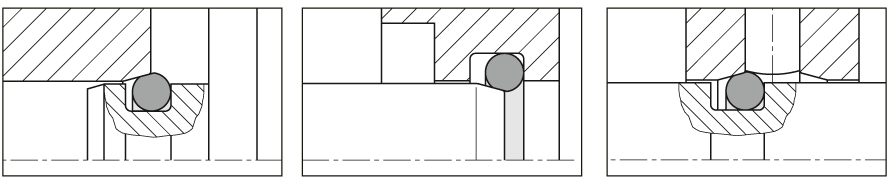

Sealing between pipes and flanges

By applying that standard, it is possible to use the groove geometry and groove dimensions for non-standard pipe or flange diameters irrespective of the nominal size of the pipes.

The construction is shown opposite as “flange sealing”. Because the groove geometry is complex in these cases, this type of static seal is only specified for cross-section diameters of 3.5 and 5 mm.

Sealing between rods and pistons

To enable the point of contact between piston and piston rods to be sealed on the same principle, a variant of this seal not specified in the standard is possible. It is shown opposite as “piston rod sealing”.

Compounds and coatings

ManoyDetect® – Metal detectable materials

In food processing and packaging industry applications ManoyDetect® enhanced materials will allow detector equipment to identify foreign matter in the processed material resulting from a damaged seal. Depending on the sensitivity of the metal detector fitted this offers a high degree of safety and will prevent contamination of the processed material.

ManoyCoat® – Anti-friction coating

ManoyCoat® coated O‑rings offer special assembly and disassembly advantages due to their anti-friction properties. For automated assembly, the coating provides smooth feeding. Various coating types are available for static applications (103, 105 and 110). Coatings 101, 102 and 106 are suitable for O‑rings in dynamic applications.

ManoyPerfluor® – For aggressive chemicals

The ManoyPerfluor® O‑ring combines the typical properties of elastomers with the almost universal resistance of PTFE. ManoyPerfluor® compounds are suitable for use with aggressive chemicals and vapours and at temperatures up to +320 °C. Also ideal for aseptic applications.