TECHNICAL DATAS

| outer sealing | outer sealing | outer sealing |

| Motion | Motion | Motion |

| linear, partially static | linear, partially static | linear, partially static |

| Direction of pressure | Direction of pressure | Direction of pressure |

| unidirectional, bidirectional | unidirectional, bidirectional | unidirectional |

| Operating pressure (MPa) | Operating pressure (MPa) | Operating pressure (MPa) |

| 120 | 30 | 120 |

| Linear speed (m/s) | Linear speed (m/s) | Linear speed (m/s) |

| 15 | 15 | 15 |

| Diameter range (mm) | Diameter range (mm) | Diameter range (mm) |

| 8 to 3000 | 8 to 3000 | 8 to 3000 |

| Housing | Housing | Housing |

| non-split (from 15 mm Ø) |

non-split (from 15 mm Ø) |

non-split (from 20 mm Ø) |

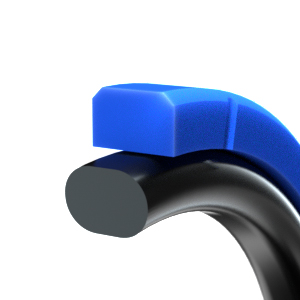

| Type 112 | outer sealing |

|---|---|

| Motion | linear, partially static |

| Direction of pressure | unidirectional, bidirectional |

| Operating pressure (MPa) | 120 |

| Linear speed (m/s) | 15 |

| Diameter range (mm) | 8 to 3000 |

| Housing | non-split (from 15 mm Ø) |

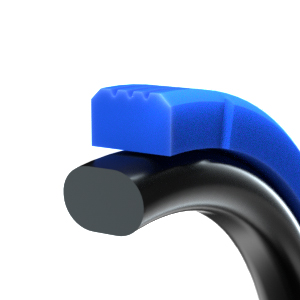

| Type 113 | outer sealing |

| Motion | linear, partially static |

| Direction of pressure | unidirectional, bidirectional |

| Operating pressure (MPa) | 30 |

| Linear speed (m/s) | 15 |

| Diameter range (mm) | 8 to 3000 |

| Housing | non-split (from 15 mm Ø) |

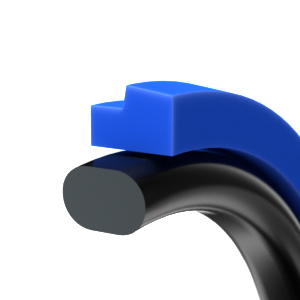

| Type 114 | outer sealing |

| Motion | linear, partially static |

| Direction of pressure | unidirectional |

| Operating pressure (MPa) | 120 |

| Linear speed (m/s) | 15 |

| Diameter range (mm) | 8 to 3000 |

| Housing | non-split (from 20 mm Ø) |