TECHNICAL DATAS

| outer sealing | outer sealing | inner sealing | inner sealing |

| Motion | Motion | Motion | Motion |

| rotary, partially static, partially linear | rotary, partially static, partially linear | rotary, partially static, partially linear | rotary, partially static, partially linear |

| Direction of pressure | Direction of pressure | Direction of pressure | Direction of pressure |

| unidirectional | unidirectional, bidirectional | unidirectional | unidirectional, bidirectional |

| Operating pressure (MPa) | Operating pressure (MPa) | Operating pressure (MPa) | Operating pressure (MPa) |

| 15 | 15 | 15 | 15 |

| Rotary speed (m/s) | Rotary speed (m/s) | Rotary speed (m/s) | Rotary speed (m/s) |

| 3 | 3 | 3 | 3 |

| Diameter range (mm) | Diameter range (mm) | Diameter range (mm) | Diameter range (mm) |

| 8 to 2000 | 8 to 2000 | 6 to 2000 | 6 to 2000 |

| Housing | Housing | Housing | Housing |

| non-split (from 14 mm Ø) |

non-split (from 14 mm Ø) |

non-split (from 25 mm Ø) |

non-split (from 25 mm Ø) |

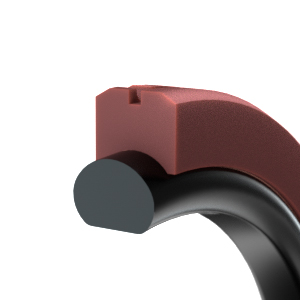

| Type 231 | outer sealing |

|---|---|

| Motion | rotary, partially static, partially linear |

| Direction of pressure | unidirectional |

| Operating pressure (MPa) | 15 |

| Rotary speed (m/s) | 3 |

| Diameter range (mm) | 8 to 2000 |

| Housing | non-split (from 14 mm Ø) |

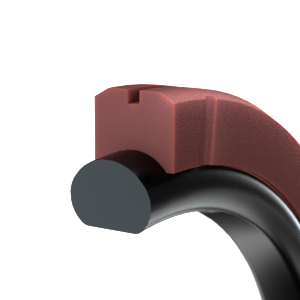

| Type 233 | outer sealing |

| Motion | rotary, partially static, partially linear |

| Direction of pressure | unidirectional, bidirectional |

| Operating pressure (MPa) | 15 |

| Rotary speed (m/s) | 3 |

| Diameter range (mm) | 8 to 2000 |

| Housing | non-split (from 14 mm Ø) |

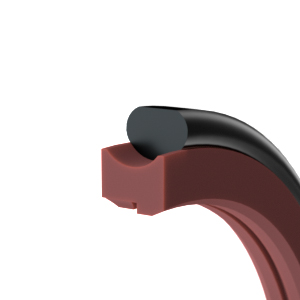

| Type 236 | inner sealing |

| Motion | rotary, partially static, partially linear |

| Direction of pressure | unidirectional |

| Operating pressure (MPa) | 15 |

| Rotary speed (m/s) | 3 |

| Diameter range (mm) | 6 to 2000 |

| Housing | non-split (from 25 mm Ø) |

| Type 238 | inner sealing |

| Motion | rotary, partially static, partially linear |

| Direction of pressure | unidirectional, bidirectional |

| Operating pressure (MPa) | 15 |

| Rotary speed (m/s) | 3 |

| Diameter range (mm) | 6 to 2000 |

| Housing | non-split (from 25 mm Ø) |